A COMMON GUIDE TO CABLE PULLERS AND CABLE GRIPS

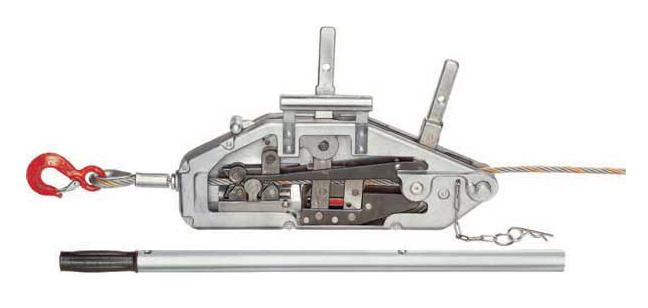

When it comes to pulling or tensioning, cable pullers and cable grips are a great tool for the job they are easy to carry around on work sites and can be used safely once the correct capacities of cable and pullers are used. Cable pullers are used a lot in industry and even for day to day use, they can be that tool that gets you out of sticky situations for example, if your car gets stuck in mud or sand, a cable puller can be used to pull out the vehicle in very little time. At its simplest it works the same as a ratchet with the handle being moved back and forth to drive the cable around the drum, pulling the load attached to the hook.

Cable pullers have many uses and in lots of different industries, it is one of those tools that comes in handy, as its size and weight make it practical, it is also known as a Come Along or a Cable winch. In this post I will discuss the various places cable pullers and cable grips are used and some of their features that make them so practical.

CABLE PULLERS, WHEN TO USE THEM

The different industries that cable pullers are used in varies from mining, factories, forestry, recreational use, construction, shipbuilding, powerline construction, refineries, civil engineering and many more, cable pullers are built for pulling lowering and tensioning and within these industries where pulling loads frequently, means a tool like this is highly valuable and used very often.

Their working load limits vary from 500kg up to 3200kg for the more heavy duty products that we have to offer. For the smaller cable puller they are practical when you need to carry a lightweight pullers as they work great in many different types of situations and environments. A lot of Cable pullers are for pulling and tensioning only. Lifting and lowering of loads is not permitted on many products and checking the products specifications before use is important.

SAFE PULLING WITH CABLE PULLERS

The safety aspect of cable pullers needs to be considered and its critical to keep a few things in mind. Cables that are badly rusted or frayed should not be used as they may pose a risk when used in the cable pullers. Catastrophic failure of a cable puller is when the cable breaks and can result in injury or damage, adding a dampener to the cable to reduce the risk of the cable coming back at speed could help avoid it hitting you if the cable breaks, this is a small precaution you can take. Also ensure the correct capacities and load weights are considered before pulling so as not to pull anything that is above the rated working load limits of the cable puller.

Cables and cable pullers should be inspected before use to make sure they are not worn or damaged, this is good practice and will ensure tools last longer and don't pose a risk to the operators. On some variants of our cable pullers they have a built in overload protection, this is a great feature to have as it offers additional protection incase the load was heavier than anticipated.

It can be a good idea to practice on lighter loads first and to pull loads that are well under your units operating capacity, this will help to familiarize yourself with how the cable puller is supposed to operate in normal working conditions. Doing this will get you familiar with the device and help you to recognise in future if the load you have attached is too much for your cable puller which could lead to overloading and risk damaging the load or injuring yourself.

I will give a brief overview of operating the cable pullers.

Please refer to your own product instruction manual before operating your cable pullers:

TO RELEASE THE CABLE OUT OF THE DRUM

Step 1 - Disengage the main ratchet drive

- Firstly locate the drive pawl spring, which is located on the lever handle, then put the spring in the up position to disengage the ratchet drive.

Step 2 - Attach the load hook

- If you have two load hooks then they can be attached to each other to form a loop then attach the load hook to the load you wish to pull.

Step 3 - The Release cable

- In order to allow the cable to run freely you must pull up the stop pawl trigger then walk back with the cable puller, this will allow the cable to be released back to your anchor point.

Step 4 - Releasing the stop pawl trigger

- After reaching the anchor point, release the trigger and then make sure it is in the ratchet sprocket position to allow for pulling to commence.

Step 5 - Attaching your anchor hook

- You can then attach your anchor hook to where you will be pulling from.

PULLING THE LOAD

Step 1 - Engage the drive

- In order to pull the load the drive must be engaged. You have to push the drive pawl spring into the down position, this will then enable the main ratchet drive to be engaged with the main ratchet drive sprocket.

Step 2 - Cranking the lever

- Cranking the lever backwards and forwards will begin to move the load by ratcheting. The load will move slowly as the lever handles is being moved back and forth.

Step 3 - Pulling the load

- Continue to move the lever handle back and forth up until the point that the load is in the desired position.

Step 4 - Secure the load

- It is important to secure the load before you release the tension this will prevent the load from moving backwards accidentally.

WHEN CAPACITY IS REDUCED

When some variants of the cable pullers are used in single fall configuration the pulling force is halved and the operating length is doubled. The cable pullers can be used in different configurations and care should be given as their WLL can then vary in certain positions. It is important to know the weight of the load that must be pulled before the operation begins and also to check the area around the load is clear, so that there are no obstacles in the way when pulling.

FEATURES OF A GOOD CABLE PULLER

When it comes to purchasing tools, everyone wants to save a bit of money here and there and as the prices of cable pullers can vary from 200 euros up to 900 euros for industrial quality cable pullers. You may be getting persuaded to go for the cheapest option, but when it comes to cable pullers you really do get what you pay for in the end as the saying goes. So it is important to take note of a few things first when it comes to buying good quality that will last. It's good to know what features are affecting the price of the cable pullers and what to look out for, here is a brief overview of the main cost factors.

- Types of Metal used – The metal that is used to build cable pullers plays a huge part in determining the manufacturing costs and how well it operates. The best choice is using high grade steel as it comes with a high shear tolerance that can keep the unit from failing under very heavy loads but with good quality metal comes a higher price tag.

-

Construction material – The frame construction is another important factor, when it comes to determining the unit strength. The better type units will use a single piece construction for the frame. When multiple pieces are bolted or welded together, this can just make for more failure points on the cable puller when in heavy use. The use of specially heat treated bolts also plays a part as they are less likely to shear off when under heavy loads. Using components made from high quality parts will ultimately last longer and is a solid investment to make.

PRODUCTS AVAILABLE FROM US

LIGHT WEIGHT CABLE PULLERS

This is Yale's Lightweight Cable Puller, which can pull loads up to 500kg, its a practical aid for pulling, lifting, tensioning and even lowering in many applications. The product is compact allowing it to be easily transported around it's a handy tool making it ideal for workshops and recreation. It is also service friendly and doesn't require much maintenance. It has stamped steel housing and comes with a complete set comprising of a cable puller with anchor bolt and telescopic operating lever, eye sling hook, 10 metres of wire rope, carrying handle and a webbing sling of 1 metre length which can be used as a rigging point for pulling or tensioning.

Yaletrac is an Aluminium Cable Puller, this range of portable cable pullers provide a versatile tool for pulling, lifting, lowering, tensioning, and securing loads over long distances upto 65 ft. they are very safe and easy to use and are almost service free as there construction is designed well, requiring only normal periodic maintenance checks. The frame is compact and lightweight with a high strength aluminum alloy housing. It has a large flat bottom surface which increases stability in horizontal and vertical working positions.

Specifically designed to be used for applications within heavy industry, building construction, civil engineering, ship building, power line construction, and oil refineries, etc. It is a product that is built to last.

Yale LM Cable Puller is built from aluminium, its a general purpose, lightweight unit that is corrosion resistant making it ideal for many industries. Its single fall and double fall configurations allow you to vary its operating length and pulling force.

CABLE PULLER MAINTENANCE

To ensure your products last a long time and keep working normally it is advised to keep certain parts of the cable pullers lubricated. This should be done periodically. It is also suggested to visually inspect your cable pullers before every use as this will ensure your product is kept in working order and free from defects, which could cause harm or damage when operating with.

CAPLE GRIPS, HOW TO USE THEM

We also have a brilliant range of cable grips which I will discuss more about, let me start by explaining what a wire or cable crip is and the role it has, it is a gripping tool which allows a user to pull and create tension on the wire rope which is fed in through it. Many applications in industry or even jobs around the home require tightening of wire rope, some applications for this include tightening of wire rope fencing. The use of wire grips allows for the quick and easy removal of slack from the wire and this helps to create a more structurally sound build than if it was merely manually tightened.

The key reason for using wire grips is safety, as tightening and tensioning of wire ropes can be a hazardous job it makes sense to use only the best and safest tools for the job, preventing accidents is paramount. When you use Yales cable grips you can be assured they provide a firm, non-slip grip without causing damage to the wire itself and are quality tested to meet high quality and tough safety regulations.

If you are interested in finding out about our cable grips in stock you can check them out on our online store.

SUMMARY

When it comes to tensioning or pulling loads cable pullers are a perfect tool to be using, they certainly make for a great addition to your tool box or in your car as it is always a good idea to be prepared for example, in more harsher climates where vehicles can get snowed in or get stuck a lot. In industry where pulling heavy loads is required our range of heavy duty cable pullers will be of great service to you they have so much to offer in terms of versatility and pulling capabilities. Our range of cable grips tie in well with other products when it comes to pulling and tensioning they are built to last and the manufacturer Yale has a fantastic reputation for durability and performance in their products. With our excellent range of cable pullers and cable grips in stock, we hope you can find one that suits your needs whether it is for personal or industrial use. To find out more check out the range of products in our online store.