The Ultimate Guide to Paving Lifter Technology

Paving lifter technology plays a crucial role in the construction industry, allowing for the efficient and safe lifting of heavy paving materials. Understanding the basics of this technology is essential in order to fully grasp its advantages and make informed decisions when selecting the right paving lifter for your project.

Understanding the basics of paving lifter technology

In construction, paving lifters are utilised to lift and transport heavy paving slabs, blocks, or stones. They provide a convenient solution for handling these materials, reducing the strain on workers and ensuring a more efficient workflow. Paving lifters are commonly used for tasks such as installing pavements, constructing walkways, and creating outdoor spaces.

The role of paving lifters in construction

In the construction industry, paving lifters are indispensable tools that enhance productivity and safety. They allow for the easy lifting and manoeuvring of heavy materials, eliminating the need for manual handling, which can lead to musculoskeletal injuries. By using paving lifters, construction teams can complete projects faster and with less physical strain on their workers.

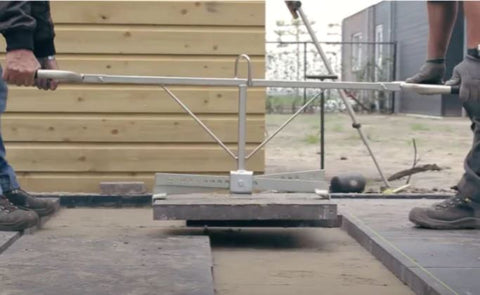

Key components of a paving lifter

A paving lifter consists of several key components that work together to provide efficient lifting capabilities. These include a sturdy frame, adjustable arms or claws, hydraulic systems, and a secure grip mechanism. The frame provides stability and support, while the adjustable arms allow for easy adaptation to various paving sizes. The hydraulic systems enable the lifter to lift heavy loads, and the secure grip mechanism ensures a firm hold on the paving material throughout the lifting process.

Moreover, modern paving lifters often come equipped with advanced features such as remote control operation and automatic levelling systems. These technological enhancements further streamline the lifting process, allowing for increased precision and control. The remote control functionality enables operators to manipulate the lifter from a distance, enhancing safety and efficiency on the construction site.

Additionally, some paving lifters are designed with telescopic arms that can extend and retract to accommodate various project requirements. This flexibility in arm length provides versatility in lifting different sizes and shapes of paving materials, making the lifter a versatile tool for a wide range of construction applications. The telescopic arms also contribute to improved reach and accessibility in challenging construction environments, ensuring that paving slabs can be lifted and placed with precision.

The evolution of paving lifter technology

Over the years, paving lifter technology has undergone significant advancements, improving efficiency and safety in construction projects. Let's take a look at the historical development and modern advancements of paving lifters.

Paving lifters have played a crucial role in construction projects for centuries, evolving from rudimentary tools to sophisticated machinery. The history of paving lifters can be traced back to ancient civilisations where manual labour was the primary method of lifting heavy materials. As time progressed, innovations in mechanical systems led to the creation of more efficient lifting devices, paving the way for the modern paving lifters we see today.

Different types of paving lifters

When selecting a paving lifter for your construction project, it's important to consider the specific requirements and constraints of the job at hand. Here, we explore two common types of paving lifters: manual and hydraulic.

Choosing the right paving lifter is crucial to ensure the smooth and efficient completion of your construction project. Factors such as the size of the paving materials, the weight of the loads, and the overall scope of the project play a significant role in determining the most suitable lifter for the job. Understanding the differences between manual and hydraulic paving lifters can help you make an informed decision that meets your project's needs.

Manual paving lifters

Manual paving lifters are simple in design and operation, requiring physical exertion from the operator to lift and carry the paving materials. These lifters are suitable for smaller projects where the lifting requirements are less demanding. Manual paving lifters offer a cost-effective solution and are comparatively lightweight and portable.

Despite their manual operation, these lifters can still provide efficient lifting capabilities for smaller-scale projects. They are often favoured for their simplicity and ease of use, making them a practical choice for DIY enthusiasts or smaller construction teams. Manual paving lifters can help streamline the process of laying paving materials, ensuring precision and accuracy in the placement of each piece.

Hydraulic paving lifters

Hydraulic paving lifters are powered by hydraulic systems, enabling them to lift heavy loads with ease. These lifters are equipped with hydraulic cylinders, which generate the necessary force to lift and transport heavy paving materials. Hydraulic lifters are ideal for larger construction projects where substantial lifting capacities are required. They offer greater versatility and efficiency, making them a popular choice among construction professionals.

The hydraulic systems in these lifters provide a smooth and controlled lifting operation, reducing the physical strain on operators and increasing overall productivity. With adjustable settings and precise control mechanisms, hydraulic paving lifters offer enhanced accuracy when positioning heavy paving materials, ensuring a seamless and professional finish to your construction project. The advanced technology and robust construction of hydraulic lifters make them a reliable and effective solution for handling heavy-duty paving tasks.

Selecting the right paving lifter for your project

Choosing the appropriate paving lifter for your construction project is crucial in ensuring its successful completion. Several factors should be considered when making this decision.

When embarking on a construction project that involves the intricate task of lifting paving materials, it is imperative to select the right paving lifter to streamline the process and enhance efficiency. The choice of paving lifter can significantly impact the overall outcome of the project, from the quality of workmanship to the timely completion of the task at hand.

Factors to consider when choosing a paving lifter

Firstly, assess the weight and size of the paving material to be lifted to determine the lifting capacity required. Consider the terrain and working conditions of the construction site, as well as any potential height restrictions. It's also essential to evaluate the available budget and the capacity of your construction team to operate and maintain the chosen paving lifter.

Furthermore, the frequency of use and the duration of the project should also be taken into account when selecting a paving lifter. For long-term projects with heavy lifting requirements, investing in a robust and high-capacity lifter may prove to be more cost-effective in the long run, despite the initial higher investment.

Pros and cons of different paving lifters

Manual paving lifters offer affordability and portability but might require more time and physical effort to accomplish the lifting tasks. On the other hand, hydraulic paving lifters offer higher lifting capacities and increased efficiency but come at a higher cost.

Moreover, technological advancements have led to the development of electric paving lifters that combine the benefits of manual and hydraulic lifters, providing a balance between cost-effectiveness and lifting capacity. These electric lifters are gaining popularity in the construction industry for their versatility and ease of operation.

Safety measures in using paving lifters

While paving lifters greatly enhance construction site productivity, it is crucial to prioritize safety during their operation. Implementing proper safety measures is essential to prevent accidents and injuries.

Essential safety features in paving lifters

Modern paving lifters are equipped with various safety features, such as emergency stop buttons, safety switches, and overload protection systems. Regular maintenance and inspections are essential to ensure these safety features remain functional and effective.

Best practices for safe operation

To ensure safe operation, operators should receive proper training on how to operate and maintain the paving lifter effectively. Adhering to manufacturer guidelines and recommended weight limits is essential. Additionally, wearing appropriate personal protective equipment, such as safety helmets and gloves, can help minimize the risk of injury.

Conclusion

Paving lifter technology has revolutionized the construction industry by offering efficient and safe solutions for lifting heavy paving materials. By understanding the basics of this technology, the different types of paving lifters available, and the factors to consider when selecting the right lifter, construction professionals can optimize their projects and ensure the safety of their workforce. Employing proper safety measures during the operation of paving lifters is paramount to maintain a secure working environment. By staying informed about the latest advancements in paving lifter technology, construction professionals can stay ahead in the fast-paced world of construction.